Last updated: September 2025

Waste Initiatives

Nifco recognizes that the effective utilization of limited resources and the minimization of waste generation are essential for the realization of a sustainable society.

Our objectives

Nifco regards the realization of an environmentally conscious and sustainable society as a core part of its corporate mission. As a means to achieve this, we have identified “promoting resource circulation through zero waste initiatives” as one of our key material issues.

Environmental Contribution and Corporate Responsibility

・Active utilization of recycled materials

・Suppression of waste generation

・Promotion of recycling

Challenge Toward “Zero Waste” and Risk Management

・Strengthening resilience against fluctuations in raw material prices

・Measures to mitigate rising waste disposal costs

・Flexible response to tightening regulations

Nifco’s Initiatives for Realizing a Circular Economy

Nifco places a strong focus on the effective use of resources and the reuse of waste, aiming to realize a circular economy through a multi-layered approach. This spans all stages—from manufacturing, development, and design to the entire supply chain—and extends to collaboration with external partners.

Initiatives at the Manufacturing, Development, and Design Stages

Minimization of Waste in the Manufacturing Stage

・Reduction of purge waste:

We are working to reduce waste materials generated during the cleaning process of molding machines.

・Reduction of sprue waste:

We strive to minimize excess materials produced during the molding process and reduce plastic waste.

Environmental Considerations in the Development and Design Stages

・Promotion of environmentally conscious product design:

We implement designs that focus on reducing environmental impact throughout the product life cycle.

・Proposals to customers:

We actively make proposals for the introduction of environmentally friendly products to support sustainable product development.

Enhancing Resource Circulation Across the Entire Supply Chain

Nifco promotes the enhancement of resource circulation not only within the company but also throughout the entire supply chain. In collaboration with our business partners, we are engaged in the following initiatives:

・Suppression of waste emissions

・Promotion of resource recovery

・Promotion of recycling

Rule-Making and Industry Contributions Through External Collaboration

Nifco actively participates in industry rule-making and takes a leading role in driving the transition to a circular economy across the entire industry.

・Participation in public-private-academic partnerships (including the Ministry of the Environment and the Ministry of Economy, Trade and Industry)

・Collaboration with the Japan Auto Parts Industries Association (JAPIA)

Practicing Resource Conservation and Resource Recovery in the Manufacturing Process

Specific Initiatives for Resource Conservation and Waste Reuse

At Nifco, we are promoting the following initiatives to conserve resources and promote the reuse of waste:

・Reducing waste through process improvements

・Strengthening waste separation and converting waste into valuable resources

・Addressing certification challenges for the use of recycled materials

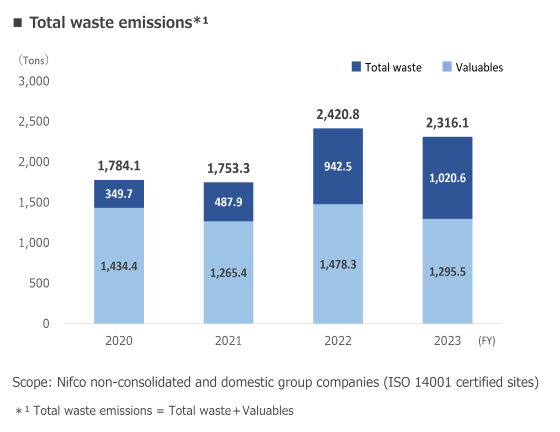

Starting in FY2024, as waste data accuracy improves, we will expand the scope of total emissions disclosure beyond ISO 14001-certified sites to include both Nifco non-consolidated sites and domestic group companies. Furthermore, among waste streams, we will designate discarded plastics as a key indicator and work toward their reduction.

Building an Innovative Recycling Model Through Industrial Collaboration

In FY2024, Nifco was selected for the "XtoCar Project," a publicly funded initiative by the Japan Foundation for Advanced Auto Recycling (J-FAR). This project aims to create new value through:

・Collaboration between upstream industries (manufacturing) and downstream industries (recycling)

・Development of an innovative recycling model that transforms waste plastics from non-automotive sources into automotive parts

As part of this project, Nifco is currently conducting research and analysis with the goal of identifying at least one type of recycled plastic material suitable for automotive applications by FY2025.

Water Resource Initiatives

Effective Use of Water Resources and Prevention of Pollution

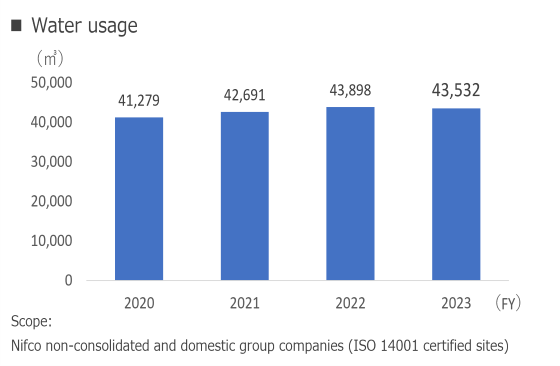

We monitor the amount of water used in our business activities and are committed to water conservation and the prevention of water pollution.

Cooling water is primarily used in air conditioning systems, molding machines, and some thermostatic chambers. We strive to reduce water usage by improving production efficiency and utilizing rainwater. In addition, we strictly comply with wastewater standards to ensure that there is no negative impact on public water bodies.

Utilization of Rainwater Harvesting Systems

Nifco Head Office

Rainwater is first stored in an underground storage tank, then filtered and disinfected before being used as flushing water for toilets. Since rainwater sufficiently serves this purpose, this initiative helps reduce the consumption of tap water, resulting in a 31.6% reduction in water usage.

Nifco Head Office Rainwater Filtration System