Last updated: September 2025

Basic Approach

At Nifco, we believe that contributing to a sustainable society through initiatives aimed at reducing CO₂ emissions from our business activities, as well as through innovation, is both our growth strategy and our commitment to sustainability. By delivering environmentally friendly products to society, we aim to play an active role in addressing environmental challenges and driving sustainable growth.

Our objectives

Under the “Carbon Neutral Declaration 2050,” Nifco has set an overall target for reducing CO₂ emissions. For Scope 1 and Scope 2 emissions across Nifco and its domestic group companies, we aim to achieve a 33% reduction in CO₂ emissions by 2030 compared to 2020 levels, and to realize carbon neutrality by 2050.

To achieve this goal, we are promoting the following initiatives.

-

Optimization of Energy Use

We are thoroughly reducing waste and inefficiencies in our production processes to achieve greater energy efficiency. -

Promotion of Renewable Energy Utilization

We are working to expand the use of renewable energy, such as through the installation of solar power generation systems. -

Development of Environmentally Friendly Products and Production Technologies

We are focusing on the development of technologies and products that reduce environmental impact throughout their entire life cycle.

Through these efforts, we are committed to achieving carbon neutrality by 2050.

CO2 Emissions Calculation Status (FY2024)

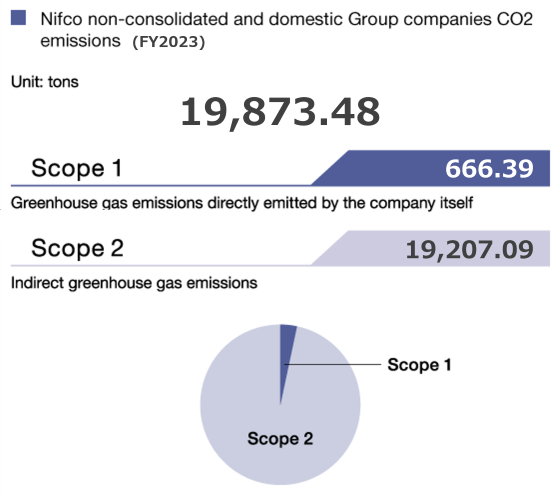

Direct Emissions (Scope 1 and Scope 2)

Nifco and its domestic group companies calculate and disclose their own greenhouse gas emissions generated from business activities.

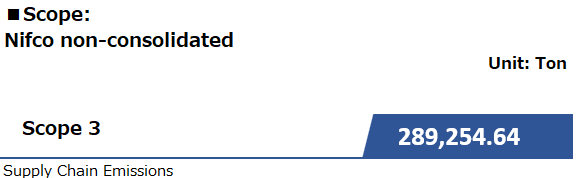

Supply Chain Emissions (Scope 3)

Regarding emissions in the supply chain (Scope 3), calculations and disclosures are currently limited to domestic business entities.

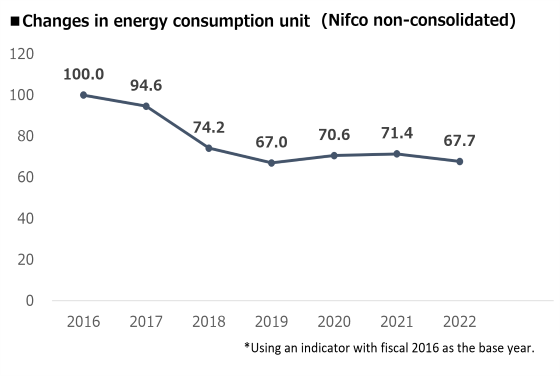

Optimization of Energy Use (Reduction of Losses and Waste)

In our annual report for fiscal year 2023 submitted in fiscal year 2024 under the Energy Conservation Act, we received an “A Class” rating under the Business Classification Evaluation System.

We have been working toward the target set by the Energy Conservation Act, which aims for an annual reduction of at least 1% in energy consumption compared to the previous year. However, we were unable to achieve this target during the reporting period.

We remain committed to continuous improvement and will continue our efforts to enhance energy efficiency.

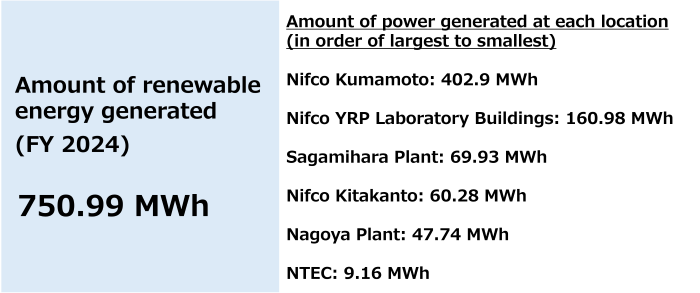

Promotion of Renewable Energy Utilization

Introduction of Solar Power Generation Systems

Nifco is actively promoting the installation of solar power generation systems to support the creation and use of renewable energy.

At our Nagoya Plant, we plan to begin operations of both an on-site Power Purchase Agreement (PPA) and off-site self-consignment schemes starting in fiscal year 2025. Through these initiatives, we aim to gradually increase the share of renewable energy used at the plant and position it as a model factory for the early achievement of carbon neutrality.

Specific targets and additional indicators regarding renewable energy utilization will be incorporated into our next Medium-Term Management Plan, which is scheduled for formulation in fiscal year 2027.

Offsetting Through FIT Non-Fossil Certificates

We have procured FIT Non-Fossil Certificates to offset Scope 2 CO₂ emissions. These certificates represent the environmental value of non-fossil energy sources, such as renewable energy, and enable us to offset CO₂ emissions associated with our electricity consumption.

In fiscal year 2024, we effectively reduced 1,221 tons of CO₂ emissions out of a total of 18,429.84 tons through the use of these certificates.

-

*

This calculation is based on the figures published by the Ministry of the Environment and the Ministry of Economy, Trade and Industry of Japan as of March 18, 2025 (Reiwa 7). The calculation covers certificates for the Nagoya Plant, using the emission factor of Chubu Electric Power Co., Inc. (0.000421 t-CO₂/kWh).

Developing new products with consideration for the global environment

Environmental risks, including climate change, are also opportunities for Clean Tech businesses. Nifco is working to reduce CO2 emissions and solve environmental problems such as air pollution by providing lightweight, high-performance plastic products. We believe that ensuring these efforts to reduce CO2 emissions and prevent air pollution is one step toward our sustainable growth. By continuing to provide cleantech opportunities aimed at responding to environmental changes and improving environmental sustainability, we aim to ensure a sustainable environment for future generations.

Opportunities in Clean Tech |

Contribution to the Environment |

Product Name |

Function Overview |

|---|---|---|---|

|

【Fuel Economy】 |

Replacing metal parts with high-performance resins reduces both weight and safety, contributing to improved fuel efficiency and reduced CO2 emissions. |

Energy absorber |

・Impact-absorbing parts that reduce damage to vehicles and passengers and enhance safety in the event of a vehicle collision. |

|

【Fuel Economy】 |

Lighter vehicle body contributes to improved fuel economy and reduced CO2 emissions |

ABS actuator bracket |

The metal bracket of the ABS actuator has been converted to resin for the first time in Japan, resulting in a weight reduction of approximately 60% while maintaining heat resistance and vibration durability. |

|

【Fuel Economy】 |

Improved vehicle running performance (reduced aerodynamic drag) contributes to improved fuel economy and reduced CO2 emissions |

Front spat |

Aerodynamic drag is reduced by channeling wind from the front of the vehicle under the vehicle floor and toward the tires. |

Ducted Air |

・Aerodynamic drag on the bumper is reduced by allowing wind from the front of the vehicle to enter the bumper. |

||

|

【Alternative Fuels】 |

Contributing to the prevention of air pollution and reduction of CO2 emissions as a component (powertrain) of FCVs capable of long-distance zero-emission driving |

FCV*parts |

This component is used in the path of hydrogen, air, water discharged after power generation, and cooling water to cool the FC stack. In addition, a Nifco filter is used in the gas path to keep foreign matter out of the FC stack. |

|

【Applications】 |

・Contributes to the reduction of carbon dioxide emissions: 50% or more reduction in electricity consumption compared to light bulbs |

Dynamic Lighting Illumination |

LED illumination inside the vehicle with the ability to visually present information on various situations to passengers |

|

【Reuse and recycling】 |

Use of recycled materials made from textiles collected and discarded at sewing factories limits reliance on virgin materials and reduces CO2 emissions |

Cord Lock/Cord Hook |

Functional parts for apparel wear made from recycled materials |

|

【Others】 |

Efficient environmental management is possible by utilizing the data measured under the environment where the sensor is installed. |

Multi sensor (three-company cooperative project) |

Self-powered sensor eliminates the need for power supply from an outlet or batteries. |

Direction of new product development

Nifco will continue to concentrate its development resources in the fields of the “environment, safety and comfort,” which are constant market trends.

By introducing products of universal value to various markets, Nifco will strive to build a business with stable and continuous growth, and it will continue to provide environmentally friendly products to realize our Purpose, “Sparking Innovation by fastening small insights with technology for a better world.”