2026/2/11

Nifco Inc. (Headquarters: Yokosuka City, Kanagawa Pref., President: Masaharu Shibao, hereinafter "Nifco") has commercialized "SoloSet™*", a system that revolutionizes the efficiency of target positioning work during automotive maintenance aiming. The company plans to exhibit the system at the 23rd International Auto Aftermarket EXPO 2026, to be held at Tokyo Big Sight from Thursday, February 12th.

*"SoloSet" is currently a trademark registration application.

In recent years, advanced safety equipment has become increasingly popular, and its installation in many automobiles has contributed greatly to reducing traffic accidents. In the future, with the development of autonomous driving technology, the number of vehicles equipped with advanced safety equipment is expected to increase further.

The automotive maintenance industry plays an important role in ensuring the ongoing safety of such equipment. However, the automotive maintenance industry is facing serious social issues such as "a chronic labor shortage and aging workforce", despite "the growing need to quickly maintain increasingly sophisticated advanced safety equipment". In particular, the aiming (calibration) of sensors required after vehicle maintenance requires a deep understanding of cutting-edge vehicle systems, including ADAS (Advanced Driver-Assistance Systems), as well as advanced specialized knowledge.

Furthermore, the "positioning" process for setting targets during aiming is crucial for verifying that various ADAS sensors are installed correctly and for recalibrating the sensor's field of view (FOV) to the same level as when the vehicle was shipped. This process requires high accuracy and high reproducibility. However, most of the methods specified in maintenance manuals are analog, which limits their accuracy and reproducibility. Furthermore, the work requires two-person teams, and marking and measuring often takes more than ten minutes. As a result, an increasing number of businesses are abandoning aiming altogether due to chronic labor shortages and increased workloads. These issues directly threaten the continuity of automotive maintenance businesses and risk a decline in safety awareness at maintenance sites, so an industry-wide response is required.

Nifco has developed and commercialized a new system called "SoloSet™" which enables one person to easily and quickly perform target positioning, a part of the aiming process in automotive maintenance, with high accuracy. By combining three key components - a dedicated marker, a measurement camera, and high-precision measurement system software – "SoloSet™" achieves position measurement that combines high repeatability and accuracy. Positioning work, which previously required two people and took a long time, can now be completed by one person in a short time with high accuracy, resulting in significant improvements* in work accuracy, labor savings, and operational efficiency. This system was jointly developed with LEAG Solutions Corp. (Headquarters: Kashiwa City, Chiba Pref., President and CEO: Yoshinari Ohmori) using their high-precision marker measurement technology.

*These results are based on our company's specified evaluation criteria and verification environment. Results may vary depending on the work environment, usage conditions, etc.

<Product Features>

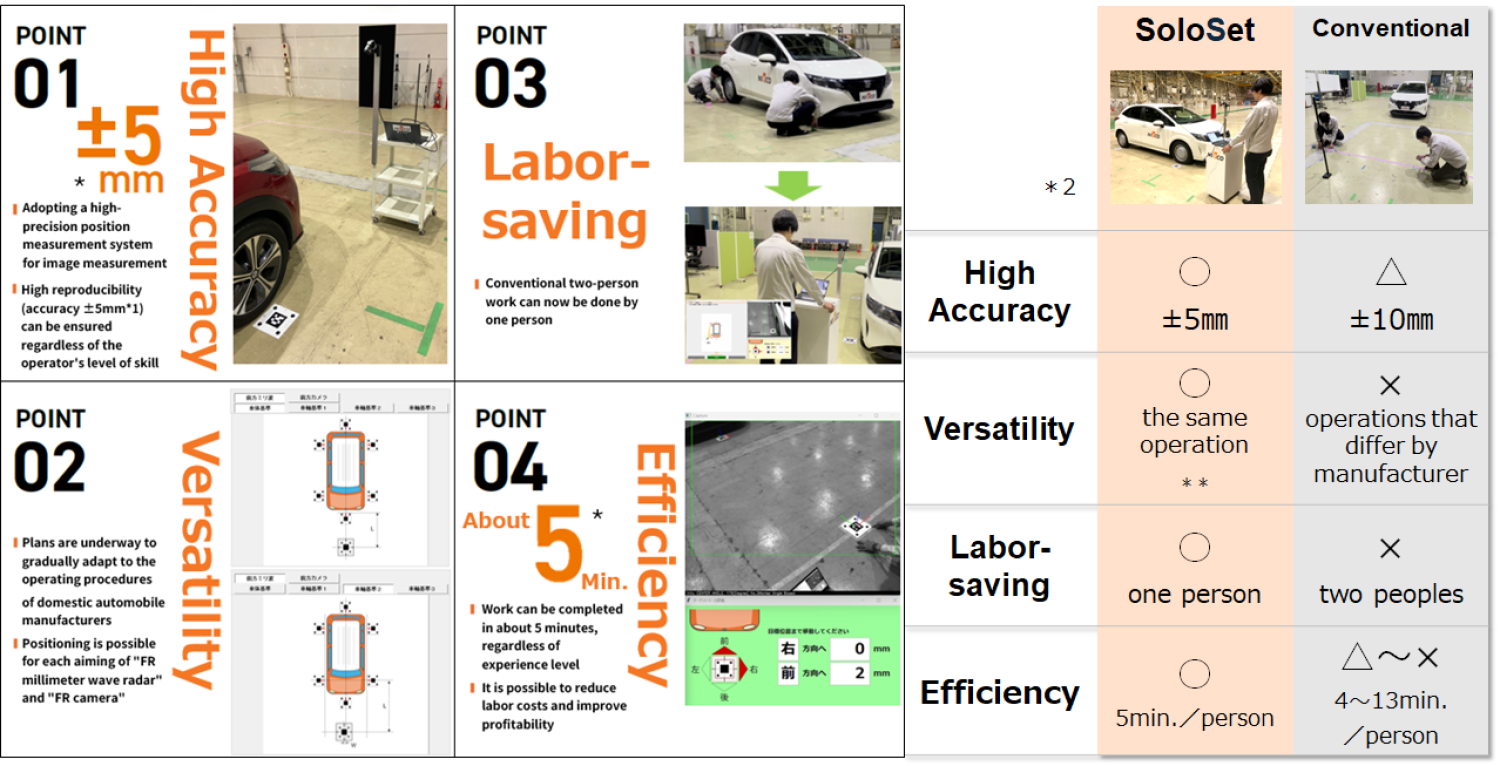

・ Point 01 High Accuracy:

Adopting a high-precision position measurement system for image measurement

High reproducibility (accuracy ±5mm*1) can be ensured regardless of the operator's level of skill

・ Point 02 Versatility:

Plans are underway to gradually adapt to the operating procedures of domestic automobile manufacturers

Positioning is possible for each aiming of "FR millimeter wave radar" and "FR camera"

・ Point 03 Labor-saving:

Conventional two-person work can now be done by one person

・ Point 04 Efficiency:

Work can be completed in about 5 minutes, regardless of experience level

It is possible to reduce labor costs and improve profitability

*1*2Based on our own evaluation criteria and verification results under our own verification environment

【Product Specifications】

● Main Components

・ High-Precision Measurement System Software (Includes USB License Activation) *3*4

・ Measurement Camera (Camera, Lens, Cable, Stand)

・ Dedicated Marker

*3 Requires installation on a Windows 11 PC

*4 Operating Environment (Minimum Requirements): Intel Core i3 or higher CPU, 8GB or more RAM,

Screen resolution 1920x1080 (FHD), USB port USB3.0x1, USB2.0x1

【Details of SoloSet™】

(Reference *Japanese text only)

In order to realize our purpose of 'Sparking innovation by fastening small insights with technology for a better world', Nifco will continue to sincerely address our customers' issues and continue to develop a variety of solutions that contribute to improving the environment, safety, and comfort in the market not only automotive parts but also in the automotive aftermarket. Furthermore, regarding improving labor productivity through labor-saving and automation, we will aim to create groundbreaking innovations through value co-creation in collaboration with external partners.

Nifco will continue to contribute to "the realization of a sustainable mobility society" throughout the entire value chain.

■LEAG Solutions Corporation. Corporate Profile

Company name:LEAG Solutions Corporation.

Head office:5-4-6 Kashiwanoha, Kashiwa City, Chiba Prefecture, 277-0882

Major products:Manufacturing, sales and consulting of high-precision marker measurement systems

Company website:leag.jp/

Please view other aiming related products here:

(Reference *Japanese text only)

Please view other Nifco products here:

For inquiries regarding this matter, please contact:

Nifco Inc., Administration Department, Administration Section.

TEL: 03-5476-4850

Email: soumu@jp.nifco.com