2025/07/25

Nifco Inc. (Headquarters: Yokosuka City, Kanagawa Pref., President: Masaharu Shibao, hereinafter “Nifco”) has recently begun demonstration test of its "Heatstroke Prevention System for Workplaces" at its Nagoya Plant and 7 client companies.

As the recent rise in temperature due to climate change has a major impact on society, the revised Labor Safety and Health Regulations came into effect in Japan on June 1, 2025, to strengthen heatstroke prevention measures in the workplace. In the places where "work for more than one continuous hour or more than four hours per day in an environment with a WBGT value (heat index) of 28 degrees or higher or a temperature of 31 degrees or higher is expected," employers are required to implement three major measures to prevent heatstroke from becoming serious: "establishing a system," "creating procedures," and "informing people whom it may concern."

Nifco has recently begun demonstration testing of a "Heatstroke Prevention System for Workplaces", which supports the implementation of all three major heatstroke prevention measures in the workplace by visualizing the situation by area and by worker.

This demonstration test began in July 2025 at our Nagoya Plant in Toyota City, Aichi Prefecture, as well as 7 client companies engaged in warehousing and manufacturing, including Kaneyoshi Corporation's Miyoshi Logistics Center.

Nifco's heatstroke prevention system has already been fully introduced at 23 public junior high schools in Yokosuka City, Kanagawa Prefecture, and Yokosuka Municipal Sogo High School , where it is being used to protect the health and safety of students in educational settings. In addition to visualizing the environment by area, as achieved in the conventional school system, the system for workplaces that we have begun the demonstration test now also visualizes temperature, humidity, and WBGT (converted) values for each worker, and also adds a function to automatically create daily checklists.

<Features of the “Heatstroke prevention system for workplaces”>

・Visualize temperature, humidity, and WBGT (converted) values by area, and alert administrators when the set values are exceeded

・Visualize temperature, humidity, and WBGT (converted) values by worker, and alert administrators when the set values are exceeded

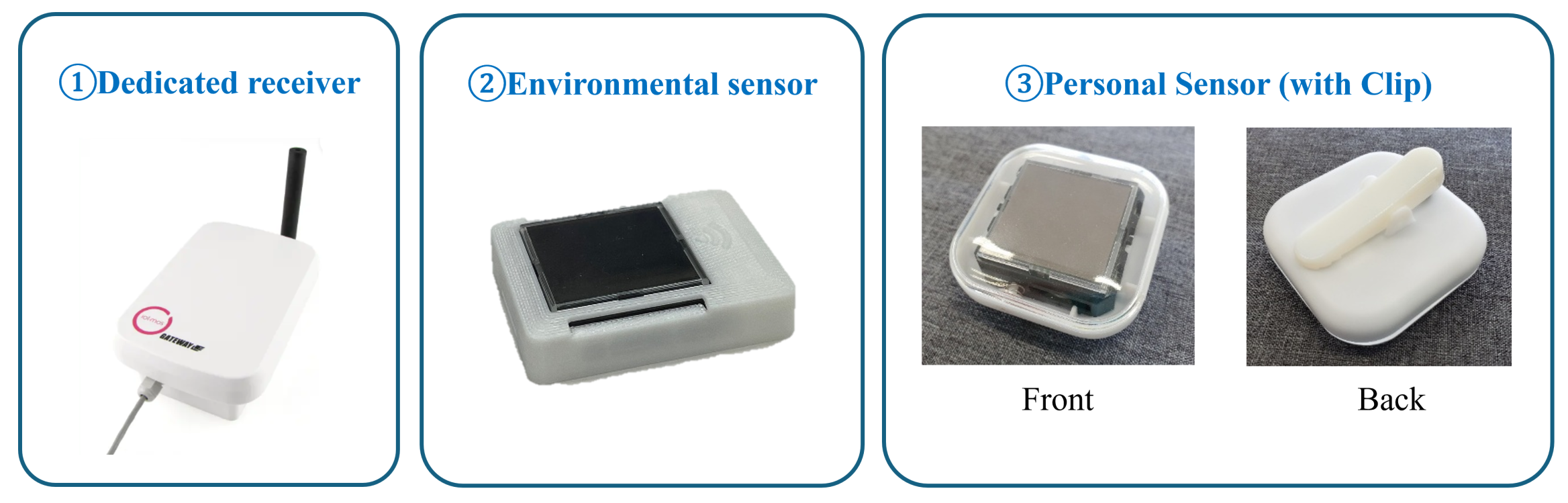

・Wireless, battery-free clip-on sensors are used to measure workers' WBGT (converted) values, making them easy to put on and take off

・Past temperature, humidity, and WBGT (converted) measurement data can be output from the system

・Daily checklists can be automatically created and output from the system

・Measurement data is accumulated and graphed, and can be used to analyze heatstroke risks by area and consider air conditioning management in facilities

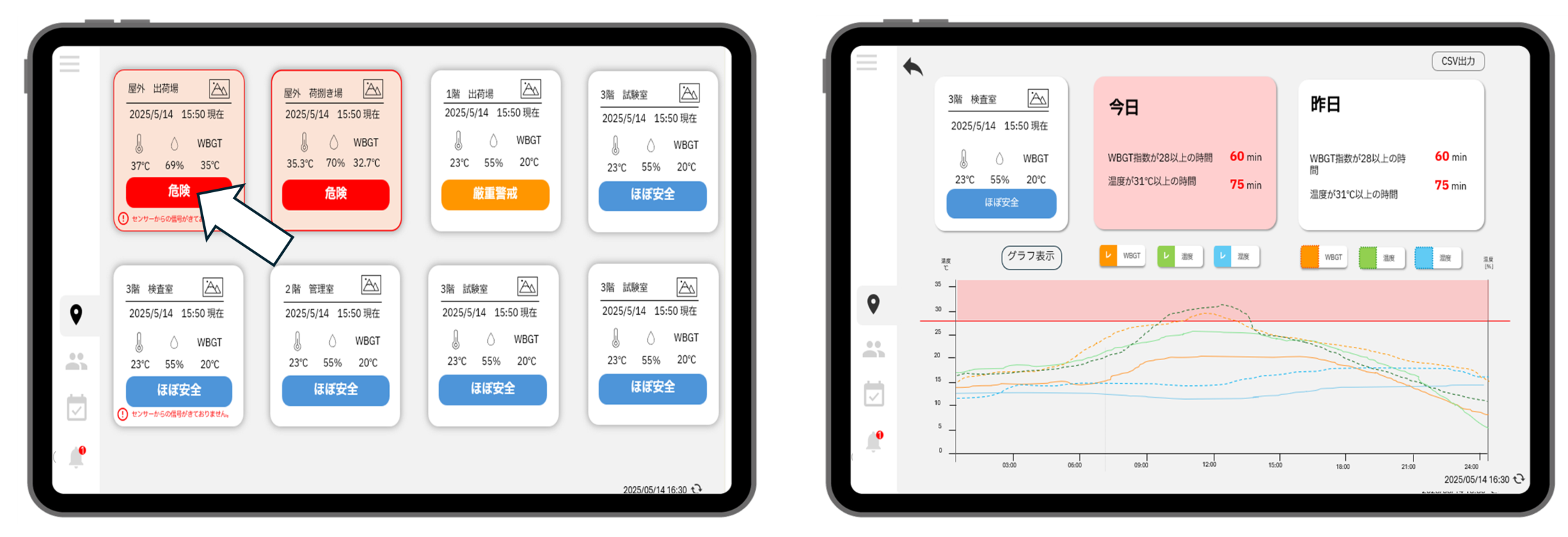

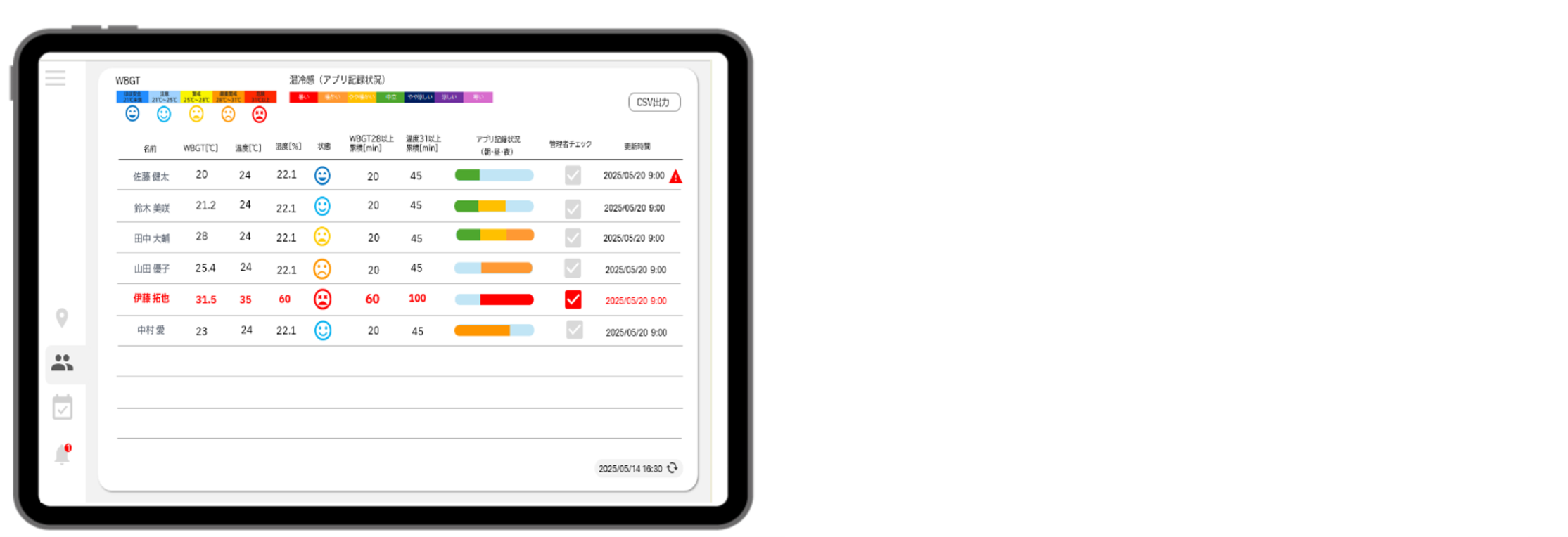

【Screen image of the system】

※The actual screen may differ due to the screen is under development.

■Data is obtained every 10 minutes for each area. The temperature, humidity and WBGT (converted) values, and heatstroke risk values are displayed.

> You can display individual details by tapping the display pop of the target area.

■Data is obtained every 10 minutes for each worker, and the temperature, humidity and WBGT (converted) values, and the heatstroke risk values are displayed.

【Equipment】

※The actual equipment may differ due to the product is under development.

This system will undergo demonstration testing until around October 2025, after which it will be verified, evaluated, and improved, and is scheduled to become available for general sale around spring 2026.

Nifco will continue to sincerely address issues from society and customers and contribute to the realization of various products that lead to a better environment, safety and comfort in order to realize our purpose of ‘Sparking innovation by fastening small insights with technology for a better world’.

Please view other Nifco products here:

For inquiries regarding this matter, please contact:

Nifco Inc., Administration Department, Administration Section.

TEL: 03-5476-4850

Email: soumu@jp.nifco.com

(Reference *Japanese text only)