2025/06/02

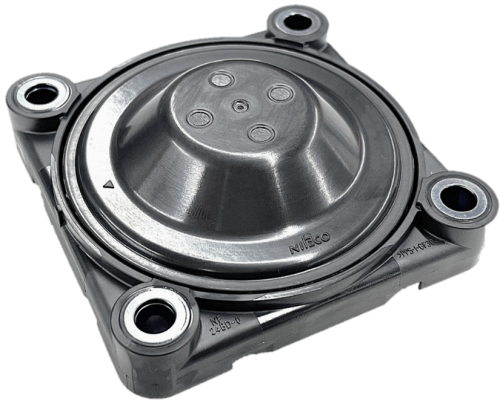

Nifco Inc. (Headquarters: Yokosuka City, Kanagawa Pref., President: Masaharu Shibao, hereinafter “Nifco”) began mass production of reclosable pressure relief valves (release valves and explosion-proof valves) with high flow-rate for Lithium-Ion battery packs that can be used in a wide range of applications.

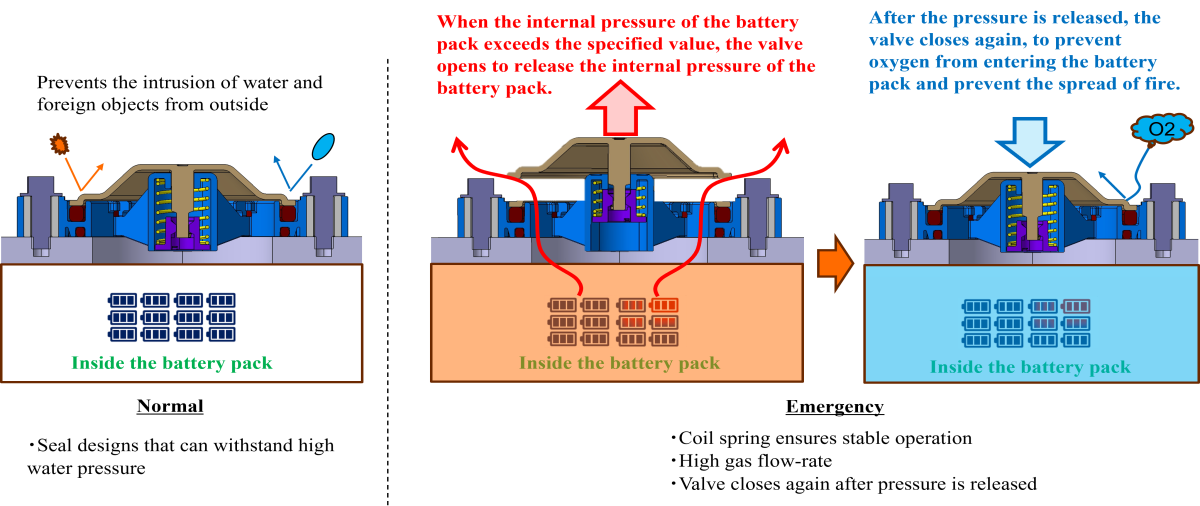

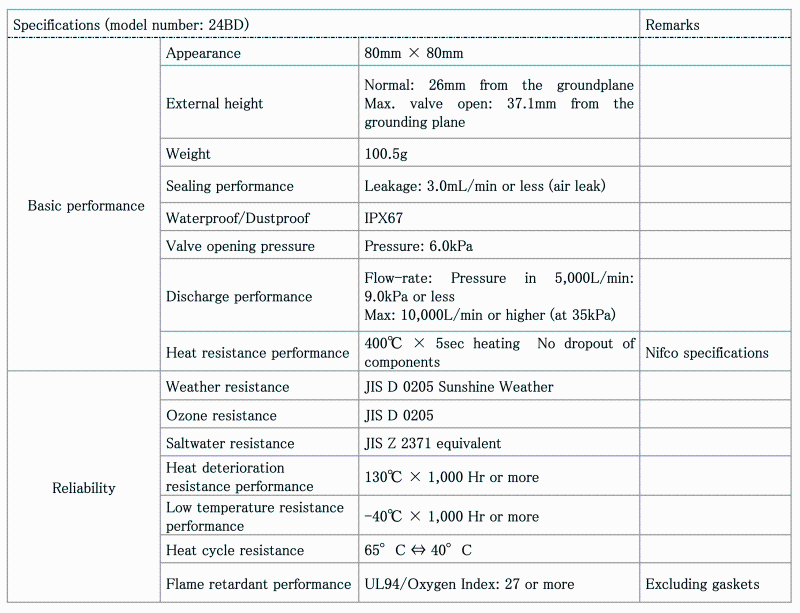

Lithium-ion batteries used in electric vehicles such as electric vehicles (BEV) and hybrid vehicles (HEV), which have been rapidly expanding in the marketplace recently, generate a large amount of gas in case of thermal runaway, which leads to the pressure increase inside the battery pack and a danger of explosion. The pressure relief valve is a product that prevents an explosion by opening the valve when the internal pressure of the battery pack exceeds the specified value and releasing the pressure to the atmosphere. Nifco's pressure relief valve, with very high discharge flow-rate at the maximum 10,000L/min (at 35kPa), releases the gas and the pressure, then closes the valve again to prevent the fire from spreading inside the battery pack. Since 2020, it has been installed in several electric vehicles manufactured by Toyota Motor Corporation. The performance and reliability of this product have been verified, as it meets the strict standards of the automobile industry.

Based on our experience in the development and manufacture of products for electric vehicles, Nifco has recently begun mass production of pressure relief valves as standard products that can be used in a wide range of applications, including not only automobiles but also industrial storage batteries, construction machinery, and personal mobility. This product is manufactured as a standard product, so it is recommended to those who wish to shorten the time required for product development or reduce the development costs or initial investment required for the development of low-volume products.

<Product Features>

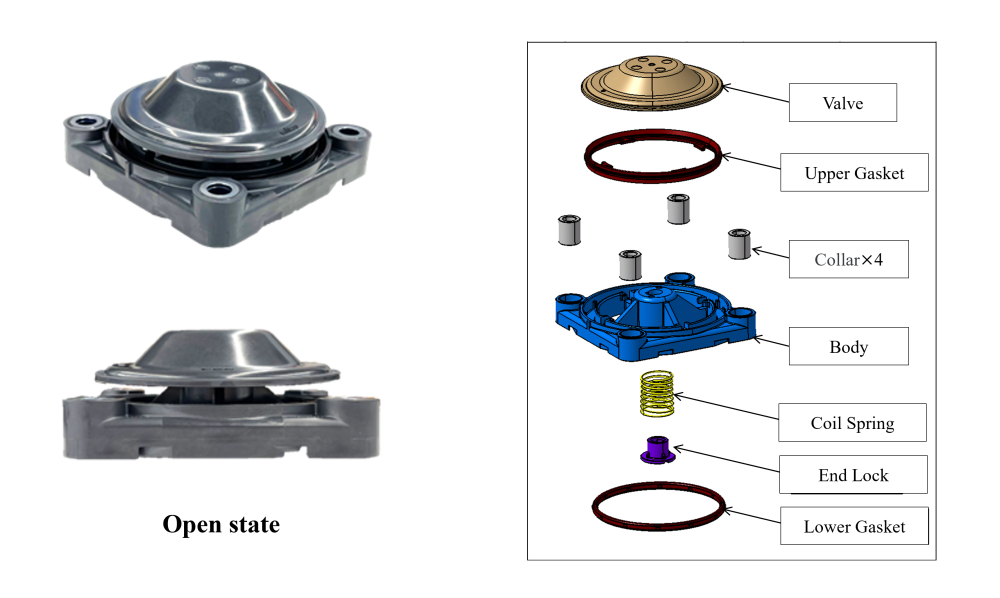

・The valve uses a coil spring, which reduces pressure drop, ensuring a high flow-rate. In addition, the valve opening pressure is stable, allowing for stable operation.

・Because of high gas-flow per unit (above max. 10,000L/min (at 35kPa)), the number of pressure relief valves s used in a battery pack can be reduced, thus production costs can also be minimized.

・After the pressure is released, the valve closes again to prevent oxygen from entering the battery pack and prevent the spread of fire.

・The seal design is able to withstand high water pressure and prevents the intrusion of water and foreign objects that can cause short circuits.

・Made of resin, it is lightweight and has high insulation against metal battery packs.

・Bolts are used to attach the battery pack to ensure stability.

【Product Features】

【Product Shape and Structure】

【Product Specifications】

Product line-up is planned to be expanded in the future.

Nifco will continue to sincerely address issues from society and customers and contribute to the realization of various products that lead to a better environment, safety and comfort in order to realize our purpose of ‘Sparking innovation by fastening small insights with technology for a better world’.

Please view other Nifco products here:

For inquiries regarding this article, please contact:

Nifco Inc., Administration Department, Administration Section.

TEL: 03-5476-4850

Email: soumu@jp.nifco.com

For inquiries regarding this product customization, please contact:

Nifco Inc., Platform Sales Department, Platform Business.

TEL: 0565-89-1592

Email: njp_smb_pfsales@jp.nifco.com

If you have any requests for customization, performance evaluation, etc., please feel free to contact us.

Customization example: Ultra-high temperature resistance, Breathable membrane add-on

Example of performance evaluation: Thermal runaway test using actual cell and module, etc.